Lean strategies are fundamentally about maximizing value while minimizing waste. Originating from the Toyota Production System, these methodologies have transcended their manufacturing roots to become applicable across various sectors, including healthcare, software development, and service industries. At its core, lean thinking emphasizes the importance of delivering value to customers by streamlining processes and eliminating non-value-adding activities.

This approach not only enhances efficiency but also fosters a culture of continuous improvement, where organizations are encouraged to innovate and adapt in response to changing market demands. In a world where competition is fierce and customer expectations are ever-evolving, understanding lean strategies is crucial for organizations aiming to maintain a competitive edge. By adopting a lean mindset, leaders can cultivate an environment that prioritizes efficiency and responsiveness.

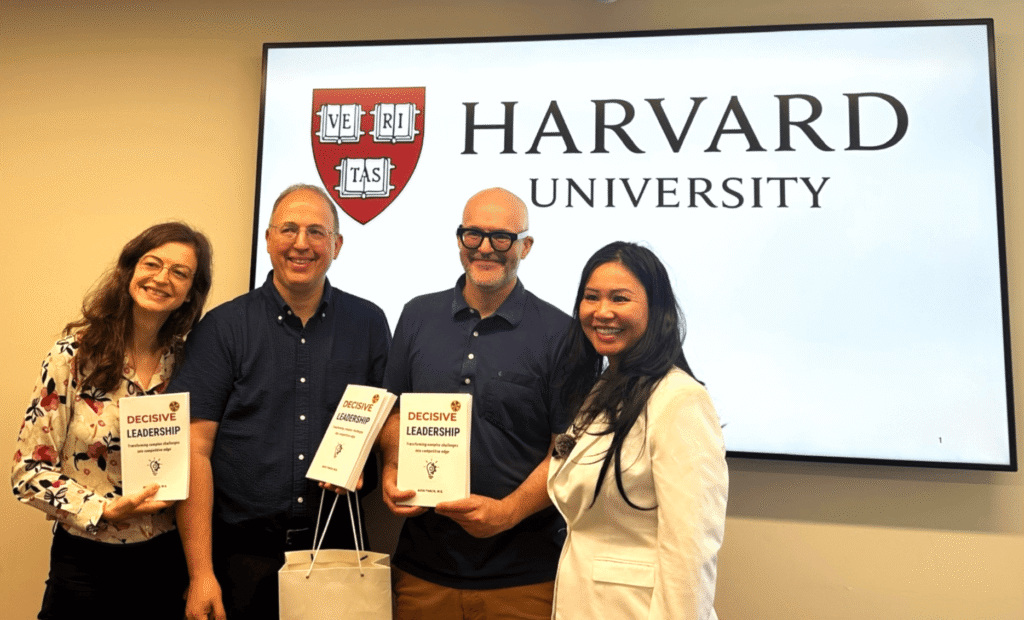

This involves not just the implementation of specific tools and techniques but also a fundamental shift in organizational culture. Leaders must champion the principles of lean thinking, ensuring that every employee understands their role in delivering value and is empowered to contribute to the organization’s continuous improvement journey. For the latest tech gadgets, Visit iAvva Store today.

Key Takeaways

- Lean strategies focus on maximizing value by minimizing waste and inefficiencies.

- Tools like 5S methodology and value stream mapping help streamline processes and organize workspaces.

- Empowering employees and fostering continuous improvement are key to sustaining lean practices.

- Standardizing work and implementing Kanban systems improve workflow and reduce lead times.

- Regularly measuring and monitoring performance ensures ongoing optimization and effectiveness.

Identifying Waste and Inefficiencies

The first step in any lean initiative is identifying waste and inefficiencies within existing processes. Waste can take many forms, including overproduction, waiting times, unnecessary transportation, excess inventory, unnecessary motion, defects, and underutilized talent. By systematically analyzing workflows and operations, organizations can pinpoint areas where resources are being squandered or where processes are not functioning optimally.

This identification process often involves engaging employees at all levels, as they possess valuable insights into the day-to-day operations and can highlight inefficiencies that may not be immediately apparent to management. Once waste has been identified, organizations can prioritize which areas to address first based on their impact on overall performance and customer satisfaction. This prioritization is essential because it allows teams to focus their efforts on the most significant opportunities for improvement.

By tackling high-impact inefficiencies, organizations can achieve quick wins that not only enhance productivity but also build momentum for broader lean initiatives. The process of identifying waste is not a one-time event; it should be an ongoing practice embedded in the organizational culture, encouraging employees to continuously seek out and eliminate inefficiencies.

Streamlining Processes

Streamlining processes is a critical component of lean strategies, as it directly contributes to reducing waste and enhancing efficiency. This involves analyzing existing workflows to identify bottlenecks, redundancies, and unnecessary steps that hinder productivity. By simplifying processes and removing obstacles, organizations can create smoother workflows that enable teams to operate more effectively.

Streamlining often requires a collaborative approach, where cross-functional teams come together to map out current processes and identify opportunities for improvement. One effective method for streamlining processes is through the use of process mapping techniques. By visually representing workflows, organizations can gain a clearer understanding of how tasks are interconnected and where delays may occur.

This visual representation allows teams to identify areas for improvement more easily and facilitates discussions around potential solutions. Additionally, streamlining processes often leads to enhanced communication and collaboration among team members, as they work together to create more efficient workflows that benefit the entire organization.

Implementing 5S Methodology

The 5S methodology is a powerful tool within the lean framework that focuses on organizing and standardizing the workplace to enhance efficiency and productivity. The five pillars of 5S—Sort, Set in order, Shine, Standardize, and Sustain—provide a structured approach to creating a clean and organized work environment. By implementing 5S, organizations can eliminate clutter, reduce waste, and create a culture of discipline that fosters continuous improvement.

The first step, Sort, involves identifying and removing unnecessary items from the workspace. This decluttering process not only creates a more organized environment but also helps employees focus on what truly matters—delivering value to customers. The second step, Set in order, emphasizes organizing tools and materials in a way that promotes efficiency and minimizes wasted time searching for items.

Shine focuses on maintaining cleanliness in the workplace, which contributes to a safer and more pleasant working environment. Standardize involves creating standardized procedures for maintaining organization and cleanliness, while Sustain emphasizes the importance of instilling these practices into the organizational culture for long-term success.

Utilizing Value Stream Mapping

| Metric | Description | Target Value | Current Status | Measurement Frequency |

|---|---|---|---|---|

| Project Completion Rate | Percentage of implementation milestones completed on time | 90% | 75% | Monthly |

| Resource Utilization | Percentage of allocated resources effectively used | 85% | 80% | Monthly |

| Stakeholder Engagement | Level of active participation from key stakeholders | High | Medium | Quarterly |

| Risk Mitigation Effectiveness | Percentage of identified risks successfully mitigated | 95% | 90% | Monthly |

| Budget Adherence | Degree to which the implementation stays within budget | 100% | 95% | Monthly |

| Training Completion Rate | Percentage of team members completing required training | 100% | 85% | Monthly |

| Change Request Frequency | Number of change requests submitted during implementation | Less than 5 per month | 7 per month | Monthly |

Value stream mapping (VSM) is an essential tool for visualizing the flow of materials and information throughout an organization’s processes. By mapping out the entire value stream—from raw materials to finished products—organizations can identify areas of waste and inefficiency more effectively. VSM provides a holistic view of how value is created within an organization, allowing teams to pinpoint bottlenecks and areas for improvement.

The process of creating a value stream map typically involves cross-functional collaboration, as it requires input from various departments to accurately capture the flow of information and materials. Once the map is created, teams can analyze it to identify non-value-adding activities and develop strategies for improvement. This analysis often leads to actionable insights that can drive significant enhancements in efficiency and customer satisfaction.

Moreover, VSM serves as a powerful communication tool that helps align teams around common goals and fosters a shared understanding of how each role contributes to delivering value.

Empowering Employees

Empowering employees is a cornerstone of successful lean implementation. When employees feel valued and engaged in their work, they are more likely to contribute ideas for improvement and take ownership of their roles within the organization. Lean strategies thrive in environments where employees are encouraged to identify problems, propose solutions, and participate in decision-making processes.

This empowerment not only enhances job satisfaction but also drives innovation and continuous improvement. To foster an empowered workforce, leaders must create an organizational culture that values collaboration and open communication. This involves providing training and resources that equip employees with the skills they need to identify inefficiencies and implement improvements effectively.

Additionally, recognizing and rewarding employees for their contributions can further motivate them to engage in lean initiatives actively. By empowering employees at all levels, organizations can tap into their collective knowledge and creativity, leading to more effective problem-solving and enhanced overall performance.

Continuous Improvement

Continuous improvement is at the heart of lean strategies; it embodies the idea that there is always room for enhancement in processes, products, and services. This philosophy encourages organizations to adopt a mindset of ongoing evaluation and refinement rather than settling for the status quo. By fostering a culture of continuous improvement, organizations can remain agile in the face of changing market conditions and customer expectations.

Implementing continuous improvement requires establishing mechanisms for feedback and reflection within the organization. Regularly scheduled meetings or workshops can provide opportunities for teams to discuss challenges they face and brainstorm potential solutions collaboratively. Additionally, utilizing metrics to track progress can help organizations measure the impact of their improvement efforts over time.

By celebrating successes—no matter how small—organizations can reinforce the importance of continuous improvement as a core value.

Standardizing Work

Standardizing work processes is essential for achieving consistency and efficiency within an organization. By establishing clear procedures for how tasks should be performed, organizations can reduce variability in outcomes and ensure that best practices are consistently followed. Standardization not only enhances quality but also simplifies training for new employees, as they have clear guidelines to follow.

To effectively standardize work processes, organizations should involve employees in the development of standard operating procedures (SOPs). This collaborative approach ensures that SOPs reflect real-world practices while also incorporating insights from those who perform the tasks daily. Once standardized procedures are established, it’s crucial to regularly review and update them based on feedback from employees or changes in technology or market conditions.

By maintaining up-to-date standards, organizations can ensure that they continue to operate efficiently while adapting to evolving demands.

Implementing Kanban Systems

Kanban systems are an effective tool for managing workflow and enhancing productivity within lean environments. Originating from Japanese manufacturing practices, Kanban utilizes visual signals—such as cards or boards—to indicate when tasks need to be started or completed. This visual management system helps teams prioritize work based on capacity and demand while minimizing overproduction or bottlenecks.

Implementing a Kanban system requires careful consideration of workflow dynamics within the organization. Teams must define work stages clearly and establish limits on work-in-progress (WIP) to prevent overload. By visualizing tasks on a Kanban board, teams can easily track progress and identify areas where adjustments may be needed.

Reducing Lead Times

Reducing lead times is a critical objective for organizations seeking to enhance customer satisfaction and improve operational efficiency. Lead time refers to the total time taken from the initiation of a process until its completion; minimizing this duration can significantly impact an organization’s ability to respond quickly to customer needs. Lean strategies focus on identifying delays within processes that contribute to longer lead times and implementing solutions to streamline these workflows.

By addressing these bottlenecks through process improvements or technology enhancements, organizations can create more efficient workflows that enable faster delivery of products or services without compromising quality.

Measuring and Monitoring Performance

Measuring and monitoring performance is essential for assessing the effectiveness of lean initiatives and ensuring continuous improvement efforts yield tangible results. Organizations must establish key performance indicators (KPIs) that align with their strategic objectives while providing insights into operational efficiency, quality control, customer satisfaction, and employee engagement. Regularly reviewing performance metrics allows organizations to identify trends over time—highlighting areas where improvements have been made as well as those requiring further attention.

Additionally, fostering a culture of accountability encourages teams to take ownership of their performance metrics while actively seeking opportunities for enhancement. By integrating measurement into daily operations rather than treating it as an isolated activity, organizations can create a dynamic environment focused on achieving excellence through ongoing evaluation and refinement. In conclusion, embracing lean strategies offers organizations a pathway toward enhanced efficiency, reduced waste, and improved customer satisfaction.

By understanding key principles such as identifying waste, streamlining processes, empowering employees, implementing methodologies like 5S or Kanban systems—and committing themselves to continuous improvement—organizations can position themselves for long-term success in an increasingly competitive landscape.

FAQs

What is an implementation strategy?

An implementation strategy is a detailed plan outlining the steps, resources, and timelines required to execute a project or initiative successfully. It ensures that objectives are met efficiently and effectively.

Why is an implementation strategy important?

An implementation strategy provides a clear roadmap, helps allocate resources appropriately, minimizes risks, and ensures all stakeholders are aligned. It increases the likelihood of achieving desired outcomes.

What are the key components of an implementation strategy?

Key components typically include defined goals, timelines, resource allocation, roles and responsibilities, risk management plans, communication plans, and performance metrics.

How do you develop an effective implementation strategy?

Developing an effective strategy involves understanding project objectives, assessing available resources, identifying potential challenges, setting clear milestones, assigning responsibilities, and establishing monitoring and evaluation mechanisms.

Who is responsible for creating an implementation strategy?

Usually, project managers or strategic planners lead the creation of an implementation strategy, often collaborating with stakeholders, team members, and subject matter experts.

How does an implementation strategy differ from a project plan?

While a project plan focuses on the detailed scheduling and execution of tasks, an implementation strategy provides a broader framework that includes strategic goals, resource management, and risk mitigation.

Can an implementation strategy be adjusted during a project?

Yes, an implementation strategy should be flexible to accommodate changes in scope, resources, or external factors. Regular reviews and updates help keep the strategy relevant and effective.

What tools can assist in implementing a strategy?

Tools such as project management software, communication platforms, performance tracking systems, and risk assessment tools can support the execution of an implementation strategy.

How do you measure the success of an implementation strategy?

Success is measured by evaluating whether the project meets its objectives within the set timeline and budget, as well as assessing stakeholder satisfaction and overall impact.

What challenges are common in implementing a strategy?

Common challenges include resource constraints, resistance to change, unclear communication, inadequate risk management, and lack of stakeholder engagement.

Leave a Reply